Introduction to the Project

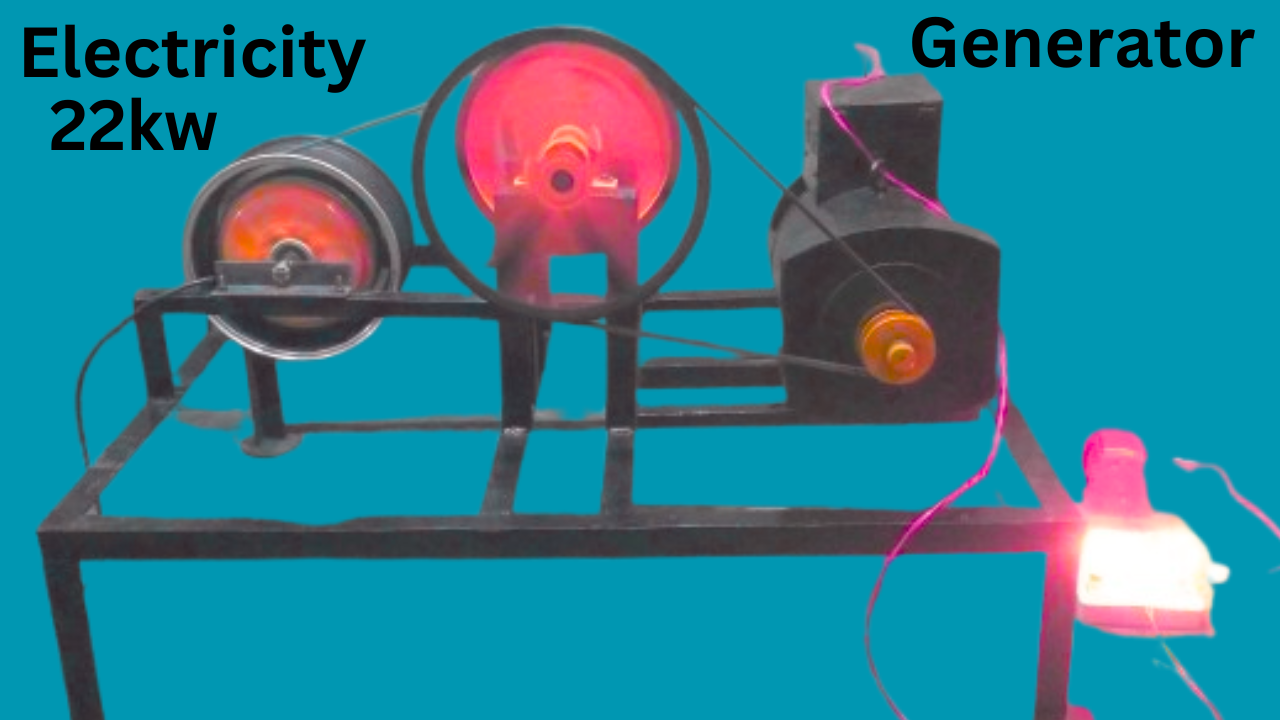

The project at hand focuses on constructing a 22 kW electricity generator, leveraging a 72-volt Brushless Direct Current (BLDC) electric wheel as a core component. The motivation to embark on this experiment stems from the growing need for sustainable energy solutions that are both efficient and practical. With the persistent rise in energy demand globally, there is an increased interest in alternative energy sources. This project seeks to explore the potential of a BLDC electric wheel not only as a means of propulsion but also as a powerful generator for electricity production.

Throughout this experiment, we will gather insights into how the conversion of mechanical energy into electrical energy can be achieved using advanced technology. The electricity generated from this system can have various applications, from powering electric vehicles to contributing towards residential energy needs, or enhancing renewable energy systems such as wind or solar setups. The implications of this project extend beyond mere electricity generation; they pave the way for further exploration into hybrid systems that might enhance energy efficiency.

As we delve into the specifics of the components utilized, the BLDC electric wheel will play a critical role given its high efficiency and durability. Its specifications, including voltage ratings and power output capacity, will be pivotal in determining its effectiveness as a generator. Our approach will involve a meticulous selection of additional components such as inverters, controllers, and batteries that work synergistically with the electric wheel. By understanding and integrating these elements, we aim to create a comprehensive system capable of generating significant amounts of electricity while maximizing the efficiency of the entire setup.

Understanding the BLDC Electric Wheel

The 72-volt Brushless DC (BLDC) electric wheel operates on fundamental electromagnetic principles, primarily through the interaction of magnetic fields. At its core, the BLDC wheel consists of a rotor, which houses permanent magnets, and a stator featuring windings of copper wire. When the rotor spins, the magnets magnetically induce a current in the stator windings, generating electricity. This process of electromagnetic induction underscores the efficiency and effectiveness of the BLDC system in electricity generation.

The significance of the magnets within the BLDC wheel cannot be overstated. They play a crucial role in converting mechanical energy into electrical energy. The use of permanent magnets allows the motor to achieve higher energy efficiency and a compact design compared to traditional motors. The absence of brushes reduces friction and wear, leading to lower maintenance requirements and increased longevity. Moreover, the synchronous operation of the rotor and the stator ensures that energy conversion occurs at optimal efficiency levels, making the BLDC wheel especially suitable for generating electricity in a compact generator setup.

In terms of power output, the 72-volt BLDC electric wheel boasts a power rating that can compete with traditional alternatives. With the capacity to produce a substantial amount of electricity, it offers an attractive solution for various applications, including renewable energy generation and electric vehicles. The BLDC’s ability to deliver consistent power while minimizing energy losses positions it as a compelling option for those looking to create an efficient electricity generator. The innovative design and operational mechanisms of the BLDC electric wheel exemplify the advancements in electric motor technology, paving the way for sustainable energy solutions and enhanced energy efficiency.

Required Materials and Tools

To successfully create a 22 kW electricity generator, specific materials and tools are essential for the experiment. Each component plays a crucial role in the generator’s functionality, ensuring efficiency and reliability. Below is a comprehensive list of the required items, including specifications and recommended sources for procurement.

First on the list is the Brushless Direct Current (BLDC) electric wheel. This component is key for generating electrical power through mechanical motion. A suitable choice would be a BLDC motor with a rated power of around 22 kW. Consider purchasing from specialized electronic suppliers or online stores that provide technical specifications and user reviews.

Next, solar panels are integral to harnessing solar energy effectively. For this project, it is advised to use high-efficiency panels rated for at least 300 watts each. A minimum of 10 panels will be required, depending on your setup. Suppliers like Renogy or local solar energy firms often offer competitive prices and warranties, ensuring reliable performance.

Wiring is another fundamental component necessary for connecting the various parts of the generator. Ensure that the wiring is of appropriate gauge to handle the electrical load, preferably using copper wiring rated for at least 10 AWG. This can be sourced from hardware retailers or online electrical supply companies.

Batteries are essential for energy storage, allowing for continuous power supply. Opt for deep-cycle batteries with a minimum capacity of 200 Ah to sustain extended energy output. Local battery stores or specialty online retailers provide a range of options suited for solar setups.

In addition to these primary materials, other items such as voltage regulators, inverters, and switches should be considered to enhance your generator’s performance. Each of these components can be found at local suppliers or through reputable online retailers. By ensuring you have all the necessary materials and tools, you will be well-prepared for conducting the experiment efficiently.

Setting Up the Experiment

To create a reliable 22 kW electricity generator, it is crucial to set up the experiment methodically. Begin by gathering all necessary components, which typically include an electric wheel, solar panels, inverters, batteries, and various electrical connectors. Once the materials are in place, select a suitable area with ample space for setup and enough exposure to sunlight for the solar panels.

Start by connecting the solar panels to the electric wheel. This is often accomplished by attaching the panels to a mounting structure, ensuring they face the sun directly for optimal energy absorption. Next, install the electric wheel, making sure it is securely fixed and capable of rotating freely. The electric wheel will convert kinetic energy into electricity when driven by a mechanical force.

For enhanced clarity in this configuration, it may be helpful to refer to diagrams showing the interconnections among the components. These diagrams will outline how the outputs from the solar panels are directed to the input of the inverter, which in turn is linked to the electric wheel. Use high-quality electrical connectors to ensure a strong, efficient connection, minimizing energy loss during transmission.

After establishing these primary connections, incorporate the battery storage system. This part of the setup is essential as it stores surplus electricity, making it available for use during periods of low sunlight or high demand. Connect the batteries in parallel to optimize storage capacity while ensuring safety by following recommended guidelines. The inverter will also extend to this setup to convert the DC power stored in batteries into usable AC power.

By methodically following these steps, anyone can successfully set up a 22 kW electricity generator. Each component plays a vital role, and understanding their interdependencies is key to achieving a seamless operational system. Following the guidelines and ensuring that all connections are secure will facilitate not only a functional setup but also a repeatable process for future experiments.

Testing and Measuring Output

Once the electricity generator setup is complete, the next crucial step involves testing and measuring its output. This process not only verifies the functionality of the generator but also provides valuable data on its performance. To begin with, it is essential to ensure that all connections are secure and that the generator is free from any visible damage. Safety should be a priority; hence, wearing appropriate personal protective equipment is recommended throughout the testing process.

The first measurement to take is the voltage output. Utilizing a multimeter, set it to the appropriate voltage setting, whether AC or DC, based on your generator’s specification. By connecting the multimeter probes to the output terminals, you can obtain a reading that indicates the voltage being produced. It’s advisable to take multiple readings over a short duration to account for fluctuations, which can occur during normal operation.

Next, measuring the wattage output is essential for a comprehensive understanding of the generator’s capabilities. Wattage can be derived from the voltage and current readings, with the formula: Watts = Volts x Amps. Using the multimeter, measure the current in amperes (A) while still connected to the output. By multiplying the voltage and current measurements, you will obtain the generator’s wattage output. This metric is particularly relevant, as the goal is to achieve a consistent 22 kW output.

It is also crucial to observe any irregularities during operation. Common issues include fluctuations in voltage or excessive heating in the components. If the readings are significantly lower than expected or erratic, it may indicate problems such as a loose connection, an overloaded circuit, or potential faults in the generator components. Regular monitoring during the testing phase will not only help in identifying problems early but also aid in optimizing performance, ensuring the generator operates effectively.

Exploring the Free Energy Concept

The concept of free energy has fascinated scientists and enthusiasts alike for decades. It refers to the idea of harnessing energy from environmental sources without incurring costs associated with traditional energy generation methods. In the context of creating a 22 kW electricity generator, understanding this concept is crucial, as it forms the theoretical backbone of such endeavors.

Free energy generators aim to convert ambient energy, such as magnetic, thermal, or kinetic energy, into usable electrical energy. The theoretical underpinnings of free energy revolve around the application of advanced physics principles, including electromagnetic induction and the laws of thermodynamics. For instance, one key principle is that energy cannot be created or destroyed; rather, it can only be transformed from one form to another. This notion underlines the importance of efficiency in energy conversion processes.

When designing a free energy generator, there are specific principles that can be applied. For example, utilizing components such as magnets, coils, and rotor systems can help in capturing and converting energy effectively. However, challenges often arise when attempting to construct a device that produces more energy than it consumes. Achieving over-unity performance, where the output surpasses the input, is often met with skepticism and is a topic of ongoing debate in scientific circles.

Another consideration is the concept of energy loss due to resistance in electrical components. Effective design must include mitigation strategies to minimize these losses to achieve as much output as possible from the input source. The pursuit of free energy is not without its obstacles, leading to challenges in practical application and verification.

In the following sections, we will delve deeper into the specific components and processes involved in constructing a 22 kW electricity generator, keeping in mind the theoretical concepts of free energy that guide our project. The journey to harnessing more efficient energy generation continues to prompt inquiry and innovation within the scientific community.

Safety Precautions

When embarking on the project of creating a 22 kW electricity generator, prioritizing safety is essential. Working with electrical components involves inherent risks; therefore, it is crucial to adhere to specific safety guidelines throughout the experiment. The following precautions are designed to minimize potential hazards.

Firstly, one must always wear appropriate personal protective equipment (PPE). This includes safety goggles to protect the eyes from flying particles and electric arcs, insulated gloves to prevent electric shocks, and closed-toe shoes to safeguard feet from heavy components. Additionally, clothing should be non-flammable and fitted to prevent any entanglement with moving parts.

Next, ensure that your workspace is suitable for electrical experimentation. A dry, well-lit, and uncluttered area greatly reduces the risk of accidents. Always conduct the experiment on a non-conductive surface, and be mindful of the environmental conditions—avoid working in damp areas or outdoors during adverse weather conditions, as moisture increases the risk of electric shock.

When handling electrical components, pay attention to their ratings and specifications. Always make sure that the components used can handle the voltage and current levels associated with a 22 kW generator. It is also vital to disconnect power sources when assembling or adjusting components. This practice prevents accidental electrocution and equipment damage.

Moreover, utilize appropriate tools that are specifically designed for electrical work. Insulated tools protect against inadvertent contact with live circuits. Ensure that tools are in good condition and maintained properly. Familiarize yourself with the operational manuals of all components being used, as they may provide additional safety instructions.

Finally, working in groups is often a prudent approach. Collaborate with a partner who can assist you in case of an emergency and verify that safety protocols are being followed. By observing these precautions, you can significantly enhance the safety of the electrical experiment, thereby focusing on achieving project success without compromising safety.

Documentation and Results

Documenting the experiment is a crucial aspect of creating a 22 kW electricity generator. It serves not only as a record of the process but also as a vital learning tool for anyone engaging in this complex undertaking. Keeping a detailed account of each phase of the setup process can lead to deeper insights and a better understanding of the mechanics at play.

From the outset, it is essential to document each step meticulously, including the materials used, the layout of the components, and any deviations from the planned procedure. This thorough documentation will enable the experimenter to analyze what worked well and what areas may require improvement. Furthermore, noting the rationale behind each decision made during the setup can provide context for future experiments, enhancing the overall learning experience.

During the testing phase, results should be recorded systematically. This includes measuring output voltage, current, and any other relevant metrics that indicate the generator’s performance. Observations regarding the generator’s efficiency and operational stability should also be captured. Keeping a running log of any anomalies or unexpected results can be particularly valuable. For instance, if the generator performs poorly under specific conditions, noting these can help identify potential adjustments for subsequent tests.

Additionally, photographs and diagrams can complement written records, making it easier to visualize the configuration and modifications over time. Overall, comprehensive documentation will not only enrich the current experiment but also serve as a reference for improvements in future attempts. The importance of maintaining a detailed record cannot be overstated; it transforms the experiment into a structured learning journey, paving the way for ongoing innovation in electricity generation.

Conclusion and Future Projects

In this blog post, we explored the process of designing and constructing a 22 kW electricity generator, detailing the various steps involved in the experiment. Throughout our discussion, we focused on the importance of selecting appropriate materials, ensuring safety measures were thoroughly followed, and employing effective techniques to maximize output. The results of the experiment provided valuable insights into the power generation process, demonstrating both the feasibility and potential of DIY electricity generation solutions.

As we conclude, it is essential to acknowledge that while our project achieved its primary goal, there remain numerous opportunities for further experimentation. Enhancing the efficiency of the generator can be approached through various methods, such as optimizing the design for better airflow, incorporating advanced control systems, or experimenting with alternative energy sources. Additionally, components such as the rotor and stator can be fine-tuned to improve overall energy conversion rates, potentially boosting the output far beyond the initial specifications.

We encourage our readers to undertake their own projects and share their findings. Whether you decide to replicate our experiment or develop your unique approach, documenting your results can contribute significantly to the broader community interested in sustainable energy solutions. Your experiences and insights can foster collaborative learning, inspiring others to innovate within this exciting and evolving field.

As the landscape of electricity generation continues to change, opportunities for development abound. Look forward to potential future projects focused on integrating renewable energy technologies, such as solar or wind, with conventional generator systems. These endeavors can further enhance the sustainability of energy solutions, reducing reliance on fossil fuels and promoting a cleaner, more efficient energy future.